Sectors

Manufacturing – Automotive – Oil & Gas – Defense

DefenSe

An unbeatable toolkit for weapons effect simulations

High precision at high velocities

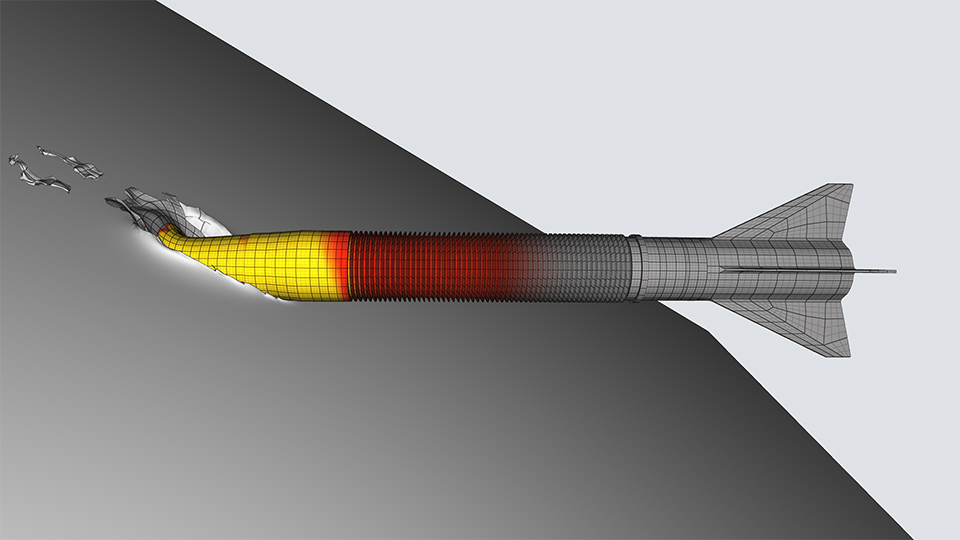

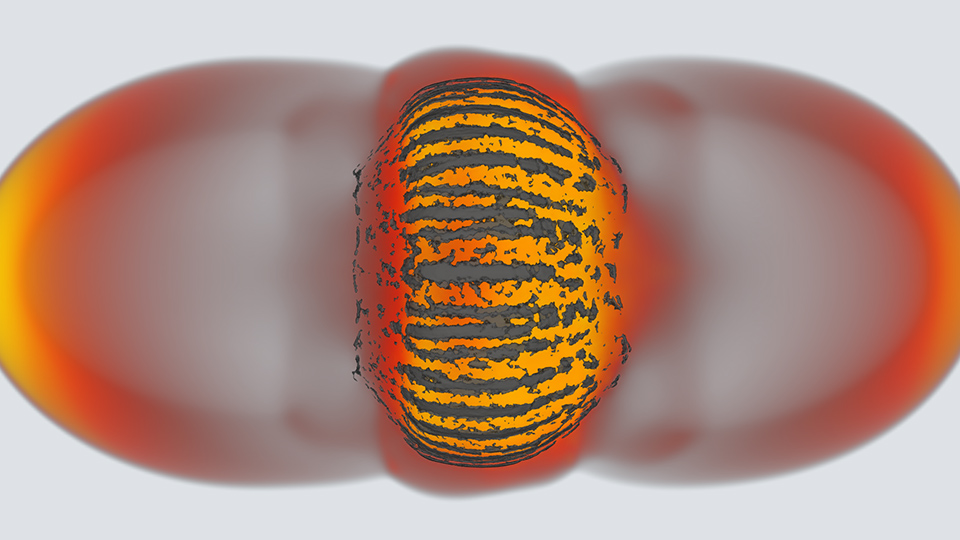

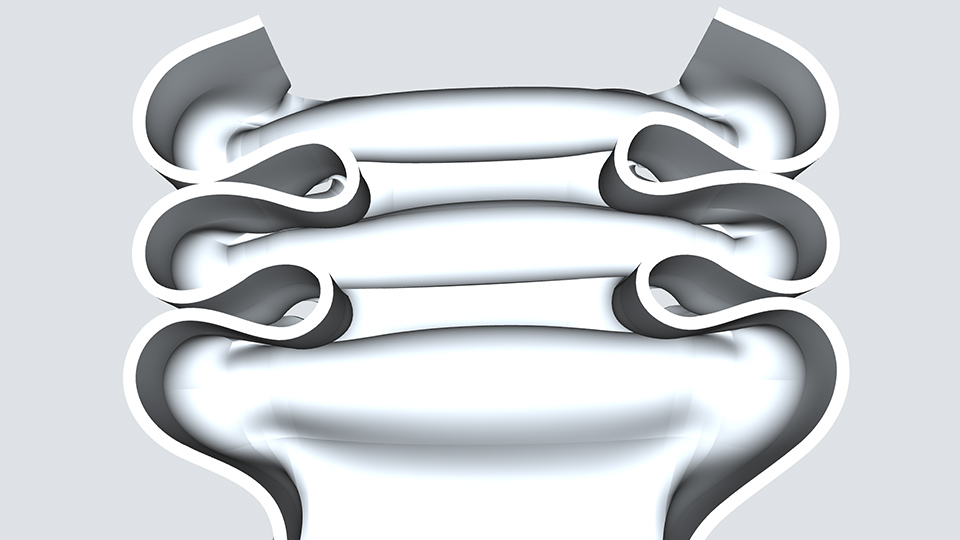

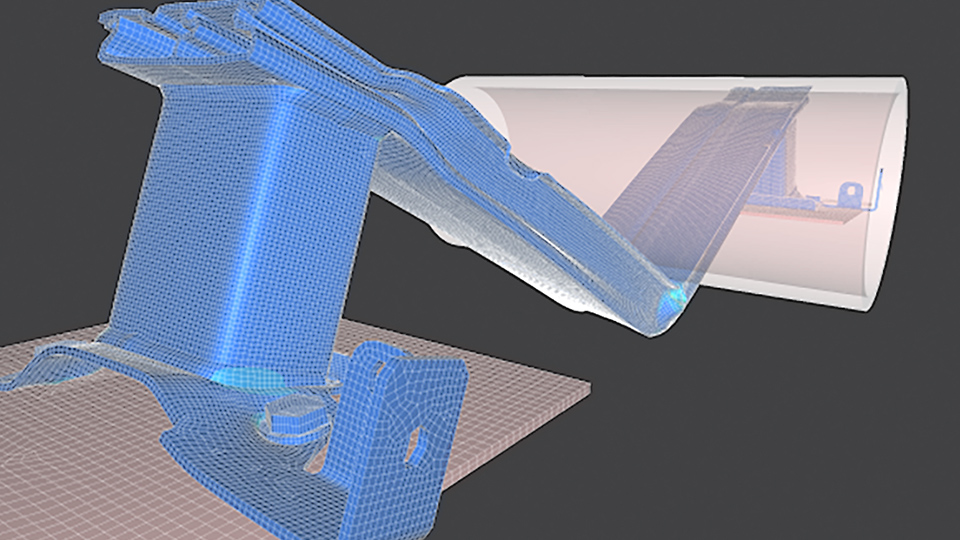

Impetus DEFENSE is our flagship product and is a powerful tool for simulating all manner of weapons effects including shaped charge formation, interior and terminal ballistics, structural response to air blasts, fragmentation, full-vehicle response to IEDs and underwater explosions.

We work closely with leading defense manufacturers and defense agencies to refine our algorithms and to ensure we provide the most robust and reliable results.

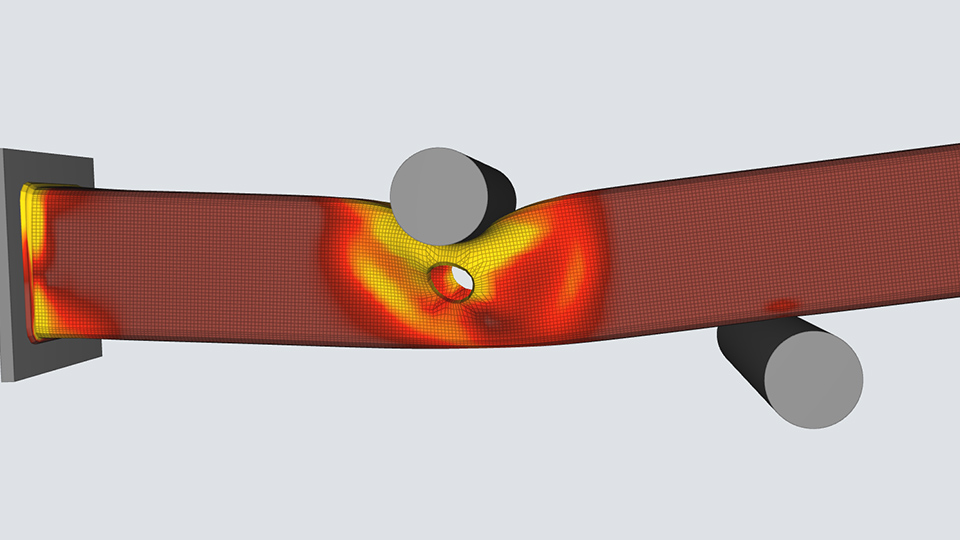

Ballistics, explosives and high velocity impacts

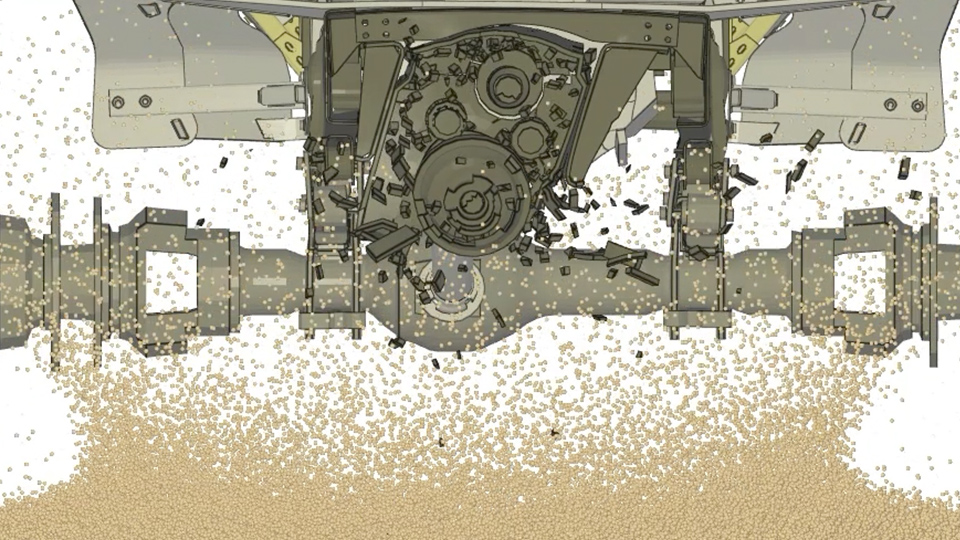

Impetus DEFENSE provides an efficient virtual test lab for defense applications to both complement and inform physical experiments. It provides for consistent methodologies in modelling structures subjected to extreme loading, the effects of shaped charges, interior ballistics and high velocity impacts. The Discrete Particle engine models high explosives interaction with sand, air and deformable structures and makes it possible to generate advanced particle structure interactions.

Our CFD engine provides for accurate simulation of explosives and gases, our Surface SPH engine is engineered to handle liquids or solid materials undergoing extreme deformations. There is also a Vulnerable Area Assessment tool for assessing survivability in protected vehicles and a V/L tool for analysis of strike patterns, velocity and impact of fragmenting explosive ordnance.

It is also possible to perform very realistic simulations of complete vehicles and/or armour systems being subjected to blast loading from IEDs buried in soil. All our computational engines are fully coupled and GPU accelerated, allowing for more efficient workflows with fewer steps and high computational performance.

Oil and gas

A powerful system for structural loading analysis

Improving safety

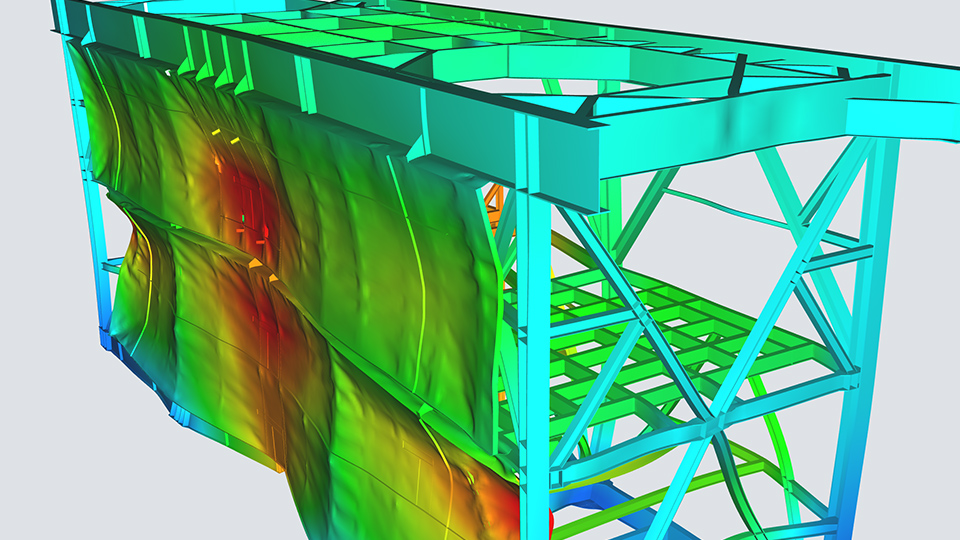

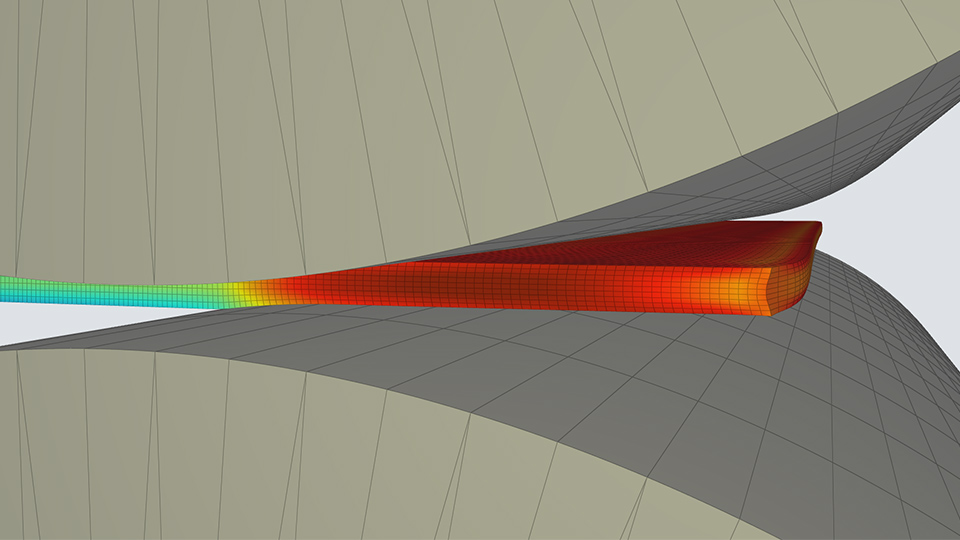

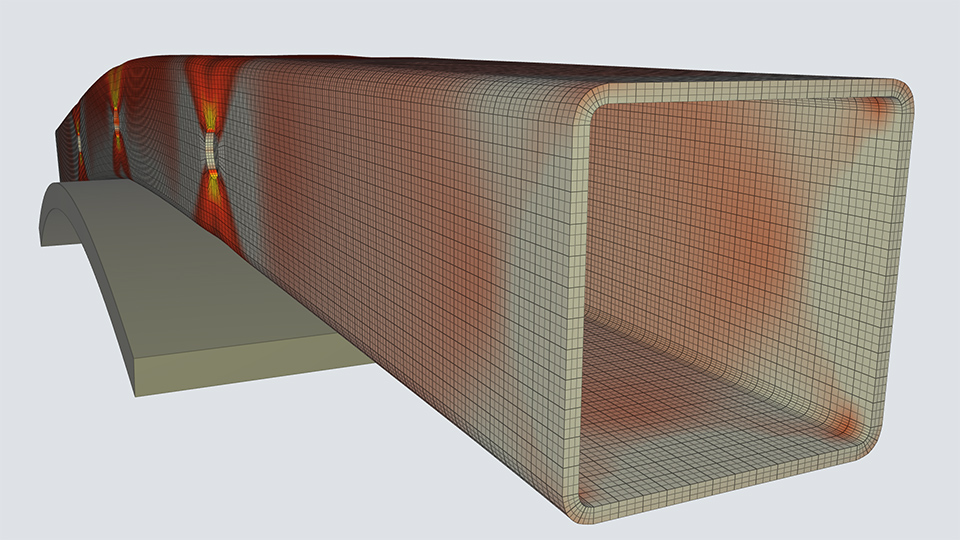

Our unique higher order element technology offers the highest precision when analysing engineering challenges within the oil and gas sector.

It is especially effective in simulating processes with large deformations of steel components at varying levels of scale. In particular with structural response to accidental loadings such as gas explosions and dropped objects.

Our products are used by leading offshore operators and have proven to provide significant time and cost savings.

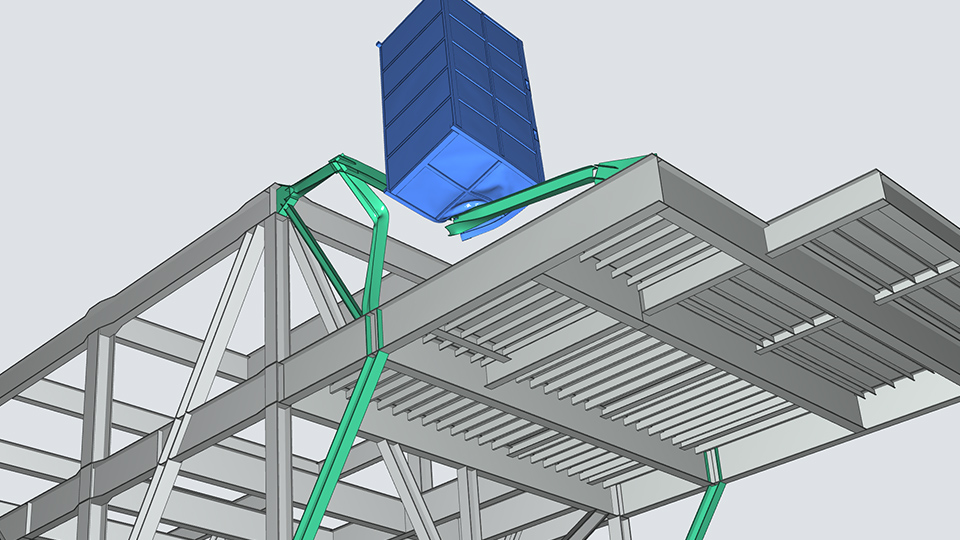

Dropped objects, accidental loading, material failure and structural collapse modes

The detailed response chain of accidental loading on complex structures are hard to estimate without numerical simulations. Often it is not cost effective or even possible to perform a full scale experiment.

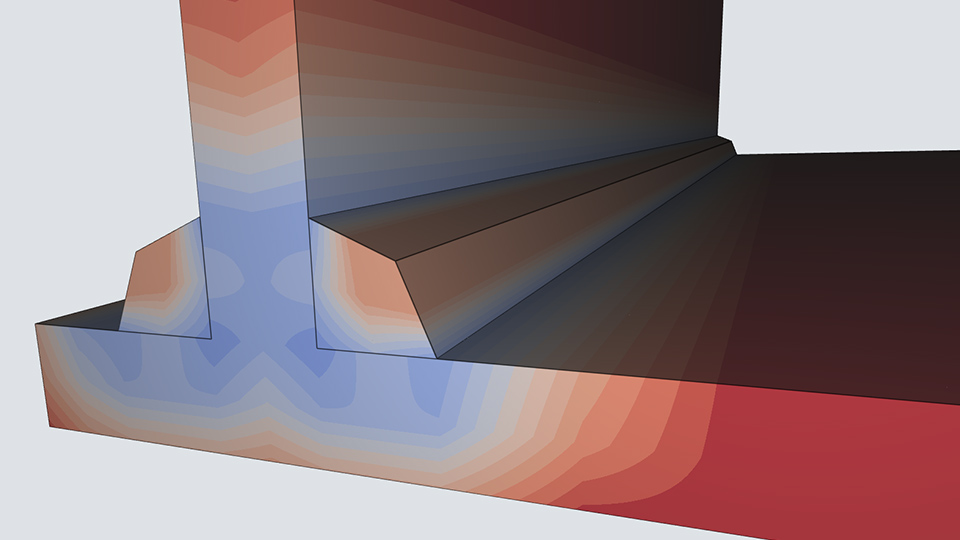

A good model will reduce the conservatism of simpler calculations and often prove that the original design loads can be greatly exceeded without compromising on the structural integrity. This can be achieved by efficient solid element models and associated material damage criteria tailor made for large-scale structures.

The advantage of our full 3D models is the possibility to visualise the accidental load response in detail, using videos with overlay of sensor data, such as deflection or material damage. This is great material for decision makers and provides a way to communicate both with customers and internally within the organisation.

manufacturing

Efficient and reliable solutions

Robust problem solving

Impetus software is an indispensable tool for our customers in the manufacturing space. Our Impetus BASIC package is based on our unique Finite Element (FE) engine which has been refined and iterated upon for over a decade.

It is the foundation for providing accurate and robust simulation results which can guide design research, product development and process optimisation in manufacturing. It is also employed to provide solid post-production analysis and improve workflow efficiency.

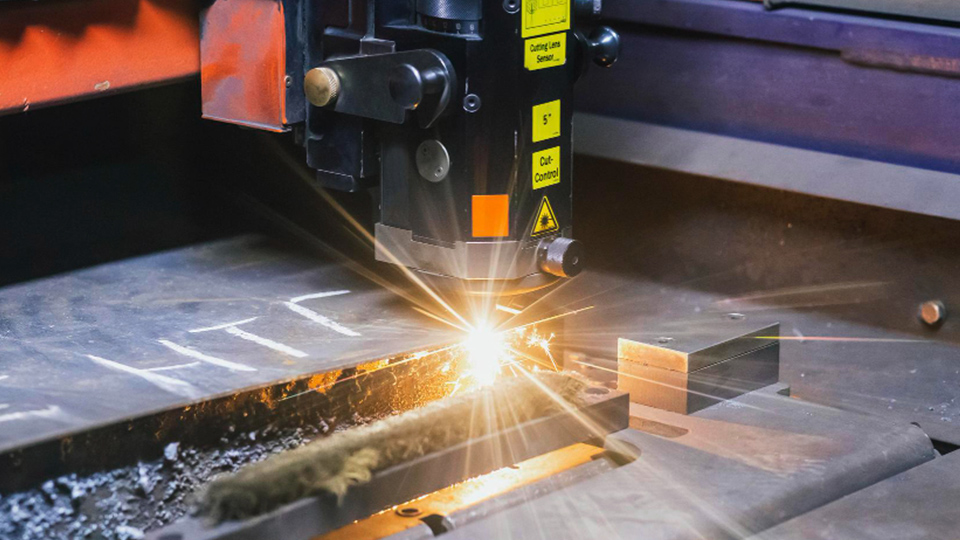

Our higher order element technology enables a whole new level of precision and detail when working with common processes such as welding, sheet metal forming, hot rolling, bolted connections and stress/strain analysis.

Cost reduction through simulation

Impetus BASIC is our civilian offering for applications requiring velocities under 500 m/s. This package is ideally suited to work with issues related to manufacturing processes and has repeatedly been shown to offer cost savings and improved results.

This has been achieved through implementing accurate simulations at earlier stages of development allowing for optimisation of design loops, shorter R&D processes, reduced reliance on physical testing and fewer iterations.

These improvements also allow for simplified workflows, and the general efficiency of our algorithms, coupled with GPU acceleration saves on computation time.

Automotive

Precise and reliable results

Streamlining processes

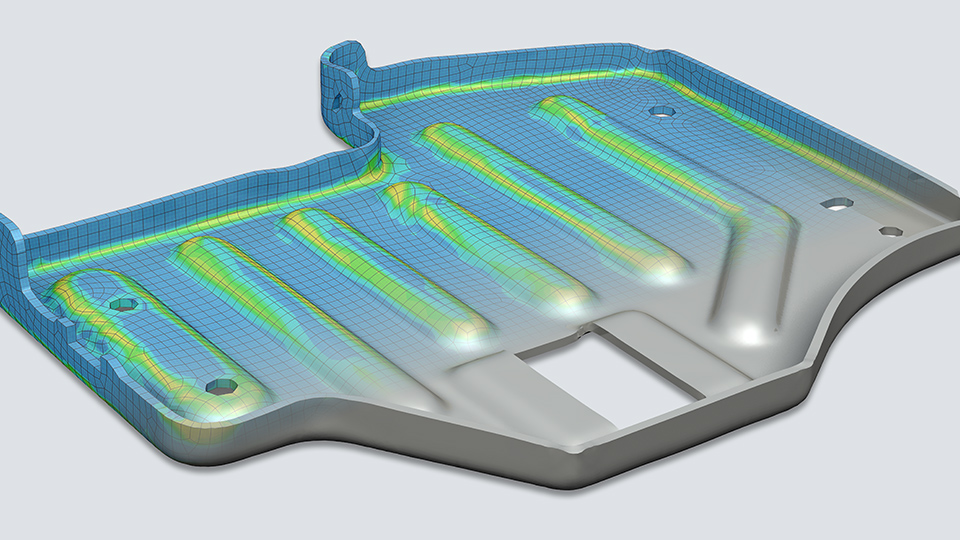

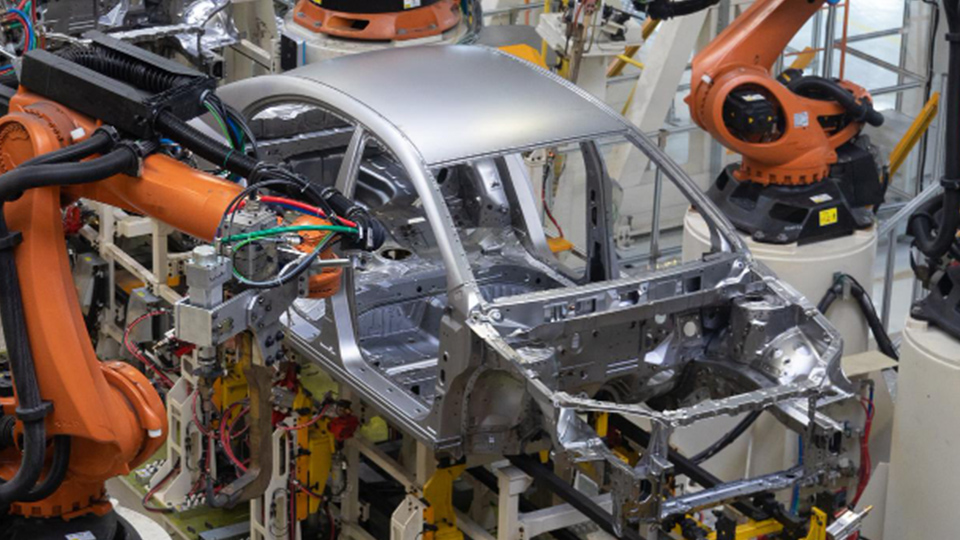

Impetus offers highly advanced solutions for design research, manufacture and testing within the automotive industry.

Our Finite Element engine is employed in developing components involving metal forming and welding operations and in crash loading experiments, simulation and subsequent analysis.

It provides consistent and robust results, with simplified workflows and with reductions in manual re-meshing and physical experimentation.

Simplify workflows, reduce iterations

The user-friendly focus of the Impetus Solver interface allows for parameterised input files and the simple initiation of parameter studies so you can easily compare response parameters to explore the domains of your process. These parameters can in turn control geometry, material, load and boundary conditions and generate reports including 2D curves, images and videos.

It is also easy to perform multi-stage analysis assessing the effect of process parameters such as forming, welding and pre-torque of bolts on the performance of your final system. And in addition, our solid element technology handles contact and boundary conditions with market-leading accuracy.

The effect of spatial discretisation can be studied by simply changing the polynomial order of our solid elements or with the use of our automatic mesh refinement functionality. Sensor information can also provide feedback to loads and boundary conditions allowing for a 1:1 representation of your real-world set-up.

Free trial

Evaluate before you buy

Try Impetus DEFENSE free for three months with full access to all features, support, and training. Our team will guide you through setup, onboarding, and evaluation so you can focus on testing the software for your needs.

Secure & scalable GPU resources

Our secure CLOUD service offers flexible access to scalable GPU processing from anywhere in the world. We are ISO 27001 certified.

Our solution provides high performance computing without the need for localised investment in hardware and maintenance.